Find Grain Bin Roof Panel Forming Machine, Bradbury Grain Bin Roof Forming Line, Automatic Silo Roof Forming Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: TG-0091

The Galvanized Steel Silo Building Machine steel coil is pulled out from the uncoiler, the steel plate is bilaterally bent by the forming machine, and then the upper and lower steel plates are occluded by the occluder to form the silo wall, and at the occlusion, the rib section which plays a strengthening role to the silo is formed. The occluder pushes the already formed silo wall spirally up and gradually forms a silo with a certain height. There is no welding point in the silo, and the rib section of the silo bite has enough air tightness. The whole silo has high preparation efficiency, short construction period, labor saving and time saving. At present, Steel Silo Roll Forming Machine is widely used in powder tank construction of Concrete Mixing Plant. This Automatic Silo Roof Machine warehouse has the advantages of installation block, large reserves, strong adaptability, low cost, easy to mechanized transportation and so on.

1. Profile Drawing and Products for Reference

2. Production Process

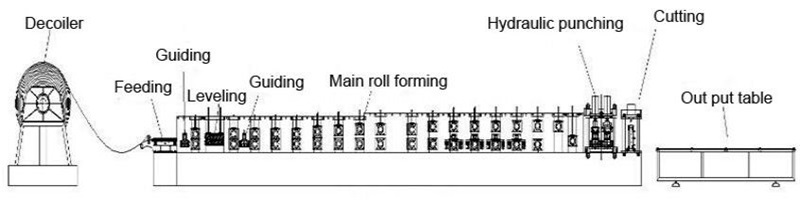

De-coiler- feeding with guide→ Straightening device→ main roll forming machine→ Curving device→ run out table

3. Constituent part

4. Machine List

| Name | Quantity |

| hydraulic decoiler(optional) | 1 set |

| Feeding&leveling device | 1 set |

| Main forming machine | 1 set |

| Gear box drive system | 1 set |

| Curving device | 1 set |

| Hydraulic Cutting device | 1 set |

| PLC control system | 1 set |

| Hydraulic station | 1 set |

| Auto stacker 6 meters(optional) | 1 set |

5. Silo Roof Panel Machine Overview

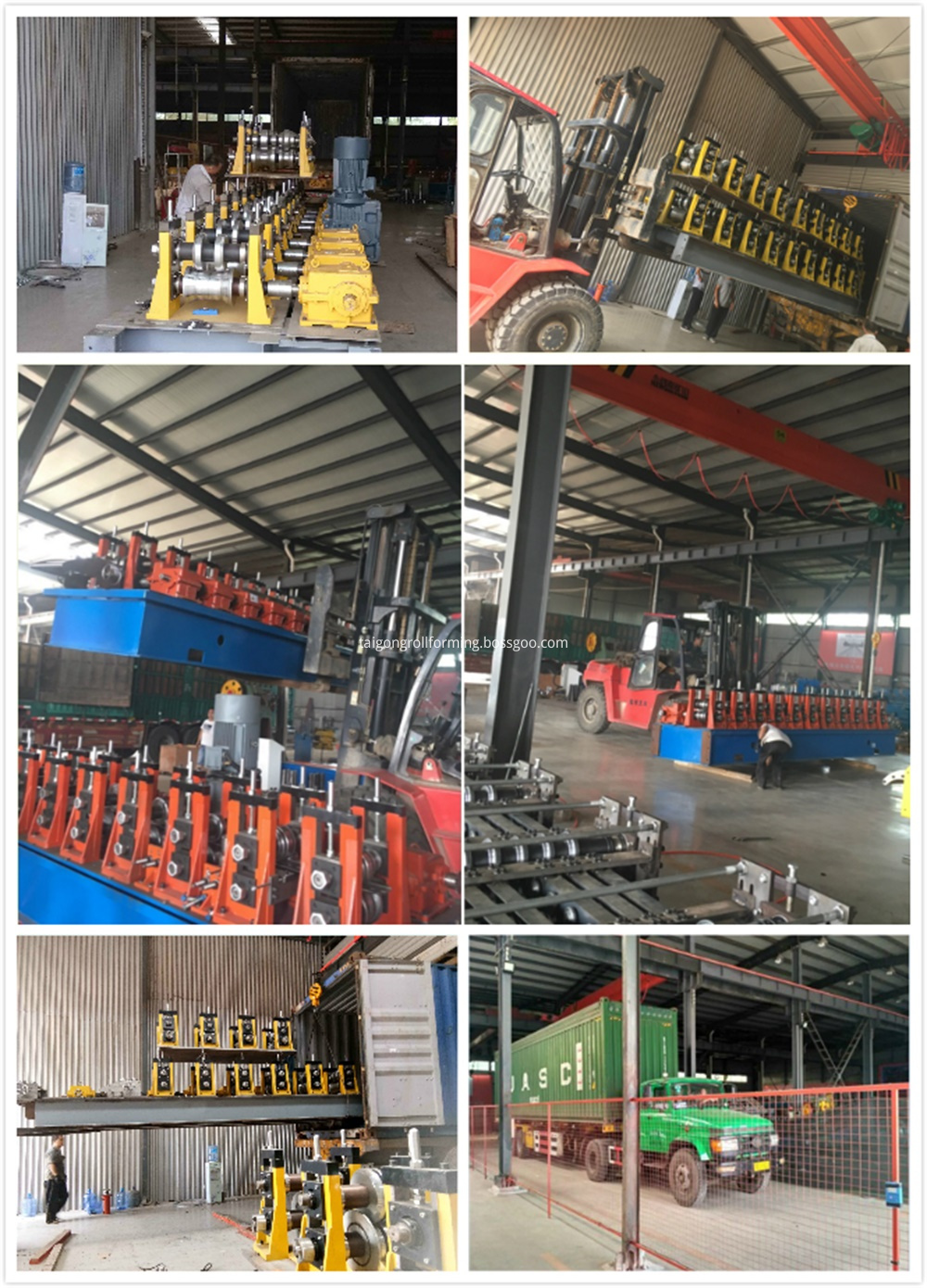

6. Scene application

7. Customer

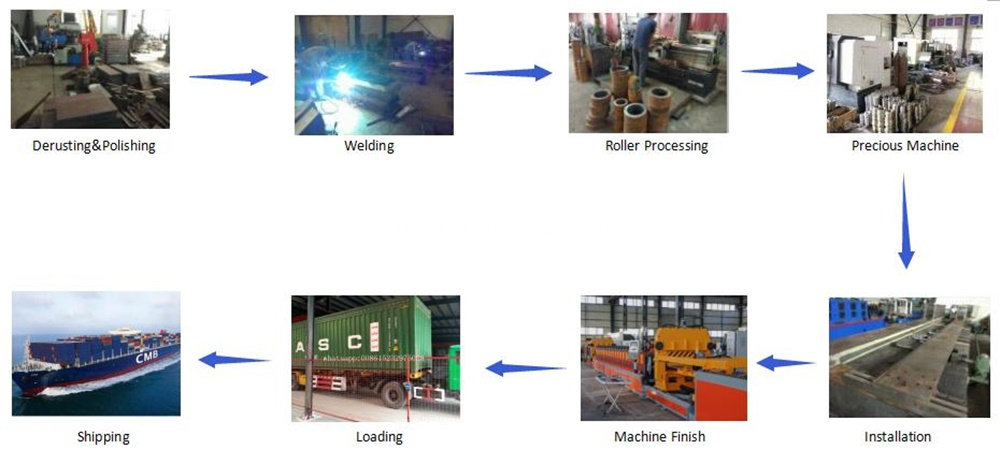

9. Loading

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 45-50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc.

6) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the Silo Roof Machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual or video to teach you to install and operate Silo Roll Forming Machine

The buyer should pay the installation charges (USD 100 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Product Categories : Silo Roll Forming Machine > Silo Roof Roll Forming Machine