Find Biomass Gasifier, Small Coal Gasifier, Biomass Gasifier For Family on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Delivery Time: | 20 Days |

|---|

Model No.: According to technical data

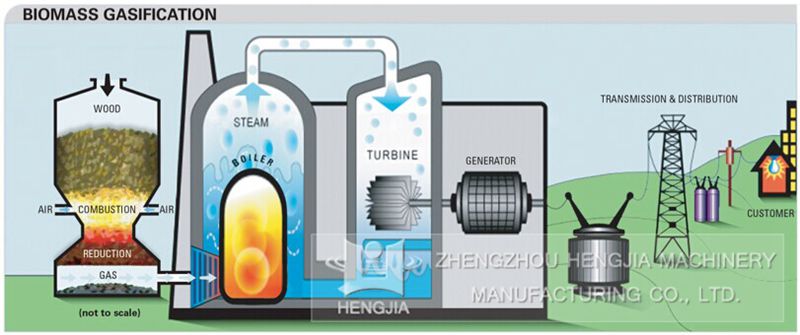

More to know Hengjia biomass gasifier ---Usage Nowadays, the most commercially successful way is to use biomass gasification for internal combustion engine. This is being widely disseminated and used, because it involves small capacity engines and features flexible in layout, small in investment, integrated in structure, reliable in technology, low in operation cost, outstanding in economic benefit, easy to maintain and operate, and is less demanding on the quality of combustible gas. ---Working process *The First step is biomass gasification, which convert biomass into syngas. **The Second step is syngas purification. The producer gas coming from gasifier usually contains contaminants including dust, coke, tar and etc. The contaminants will be removed by the purification system to ensure normal operation of gas engine. ***The Third step is power generating in gas engine. The high temperature exhaust gas may be reused by waste heat boiler to generate steam or hot water for civil or industrial use. Steam turbine may also be considered to make a gas-steam combined cycle power plant, which will increase the total efficiency.

More to know Hengjia biomass gasifier ---Usage Nowadays, the most commercially successful way is to use biomass gasification for internal combustion engine. This is being widely disseminated and used, because it involves small capacity engines and features flexible in layout, small in investment, integrated in structure, reliable in technology, low in operation cost, outstanding in economic benefit, easy to maintain and operate, and is less demanding on the quality of combustible gas. ---Working process *The First step is biomass gasification, which convert biomass into syngas. **The Second step is syngas purification. The producer gas coming from gasifier usually contains contaminants including dust, coke, tar and etc. The contaminants will be removed by the purification system to ensure normal operation of gas engine. ***The Third step is power generating in gas engine. The high temperature exhaust gas may be reused by waste heat boiler to generate steam or hot water for civil or industrial use. Steam turbine may also be considered to make a gas-steam combined cycle power plant, which will increase the total efficiency.  Technical parameters:

Technical parameters: | Item | Model | HJ-BG180 | HJ-BG360 | HJ-BG540 | HJ-BG720 | HJ-BG1200 | HJ-BG1500 | HJ-BG-1800 |

| Fuel | Fuel consumption(kg/h) | 60-120 | 120-240 | 180-360 | 240-480 | 400-800 | 500-1000 | 600-1200 |

| Fuel required | 2cm-8cm wheat straw, rice husk, wood chips, corn cob, cotton straw, peanut shell, etc. | |||||||

| Water content | 10%-15% | |||||||

| Gasification | Capacity (m3/h) | 150-180 | 300-360 | 500-540 | 600-720 | 1000-1200 | 1300-1500 | 1600-1800 |

| Composition of gas | CO:20-25% H2:8-15% CH4:2-4% CO2:2-4% N2:40-45% O2:≤1.0% | |||||||

| Rate of gasification(Nm3/kg) | Woody plants: 2-3m3 Herb plants: 1-1.5m3 | |||||||

| Electricity consumption | kw | 20 | 30 | 37 | 40 | 55 | 60 | 70 |

| Generator | Capacity (kw) | 50 | 100 | 150-200 | 250-300 | 400-500 | 600-700 | 800-900 |

| Remarks | Besides the above general models, we can also supply special model as your request. | |||||||

Product Categories : Gasifier Equipment > Biomass gasifier